The Intellectual Club meeting on the “Fracturing Technology at the Field of Ozenmunaigas JSC” was held in KMG Engineering.

- 31.08.2022

- News-Eng

- Comments Off on The Intellectual Club meeting on the “Fracturing Technology at the Field of Ozenmunaigas JSC” was held in KMG Engineering.

- sdauren

Kairat Rashidov, a Senior Engineer of the Ozenmunaigas JSC Development Department, briefed KMGE employees on the comprehensive approach to hydraulic fracturing technology in the OMG fields.

Basically, hydraulic fracturing has a positive effect, as evidenced by the selection of candidates, accurate modeling, quality hydraulic fracturing performance, and, of course, optimal well operation. The speaker listed such key success criteria in his speech.

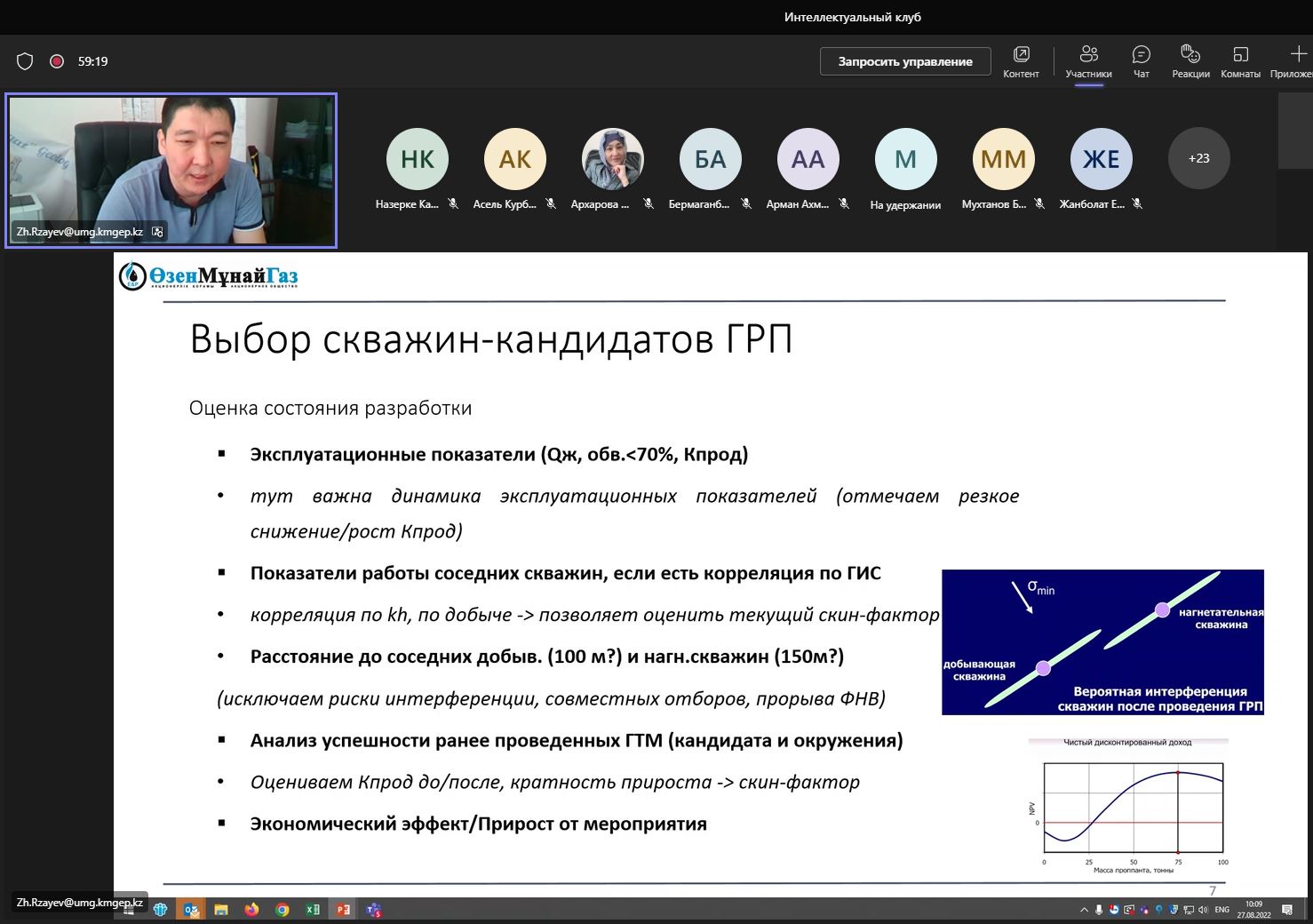

He discussed how to choose well candidates for hydraulic fracturing, as well as the data that should be considered before beginning the process:

“Collecting and analyzing information, well log interpretation results, reservoir characteristics, production data, environment, design, fluid properties, reservoir-pressure maintenance system, and many other aspects are important to consider. In addition, selection of candidate wells requires evaluation of mining and geological conditions, assessment of the development status, evaluation of the technical condition of the well, and economic efficiency/gain from hydraulic fracturing,” noted the OMG representative.

In his report, the speaker further analyzed hydraulic fracturing design simulation, focusing on a detailed review of modern hydraulic fracturing simulators, for what and how it needs to be done. In order to provide a better understanding of the subject, the engineer showed the audience a short video clip on the subject.

Concerning the development of hydraulic fracturing technologies, the speaker emphasized that currently, oil producing companies are mostly limited to using standard hydraulic fracturing technologies with polymer-based water solutions when carrying out geological and technical operations.:

“These solutions, along with killing fluids and drilling fluids, cause significant damage to the reservoir and the fracture itself, reducing the residual conductivity of fractures and, as a result, oil production. Formation and fracture damage is especially important at fields where current reservoir pressure is less than 80% of the original. For the solution of this problem, technologies using a mixture of liquid and gas are distinguished: foam liquids with a gas content of less than 52% of the total mixture and foam hydraulic fracturing with more than 52% of the gas,” summarized Kairat Rashidov in his speech.

That means that the comprehensive approach to hydraulic fracturing technology is the most relevant and in-demand technology among domestic subsoil users. Under this approach, data on well locations, formation conductivity, fracture mechanics, as well as technological limitations and economic factors are used in the design process.