How Modern Technologies are Implemented at the KMG Fields

- 06.07.2022

- News-Eng

- Comments Off on How Modern Technologies are Implemented at the KMG Fields

- sdauren

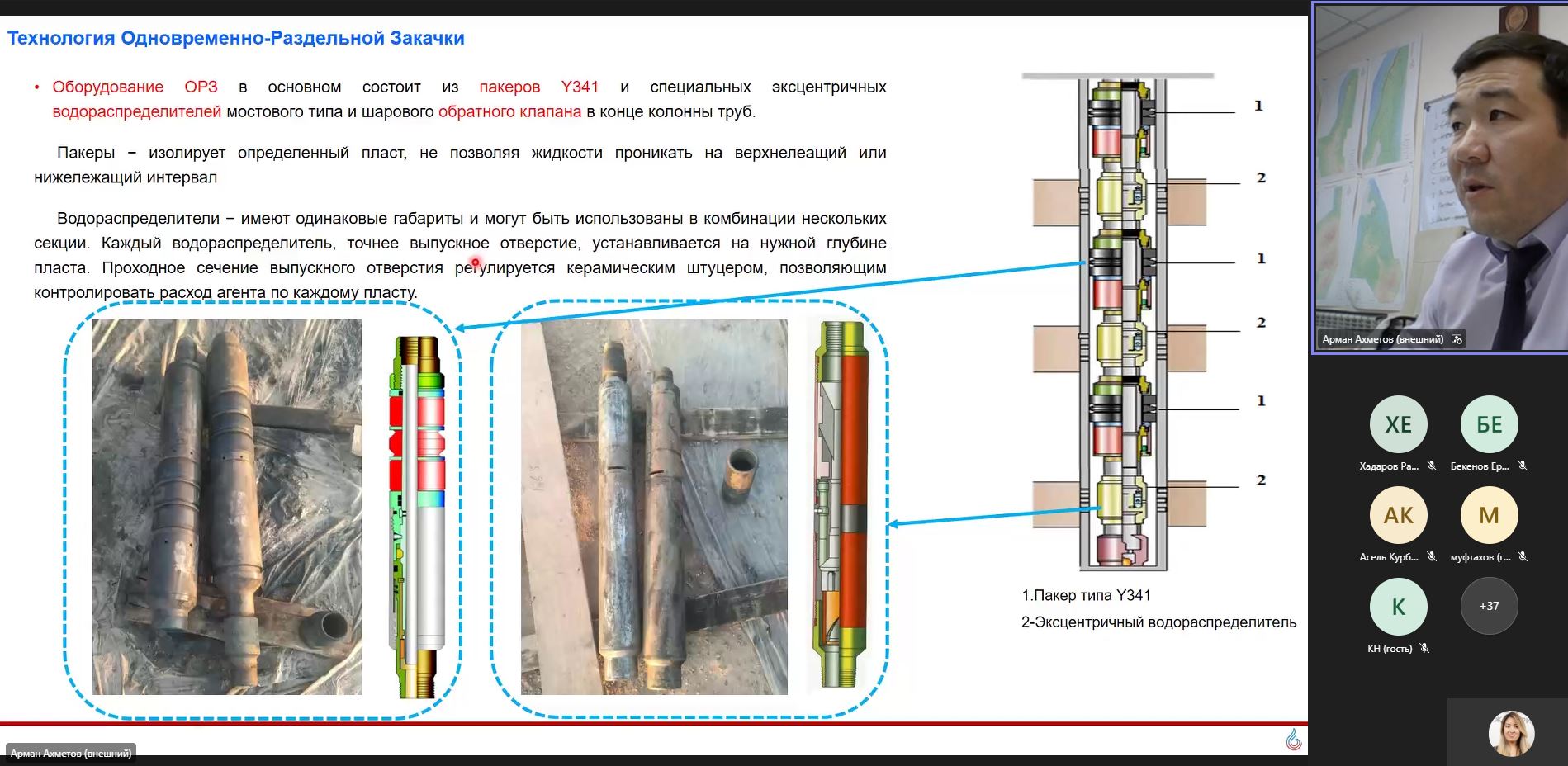

The Intellectual Club participants gathered to discuss “The Experience of Industrial Implementation of the Dual Injection Operation (DIO) Technology at the Akshabulak Central Field”.

The speaker was Arman Nurlybekuly Akhmetov, a Senior Engineer of the Field Simulation Department of JV Kazgermunai LLP. He presented a report on the horizontal geological peculiarities, DIO Technology, the main problems of the deposit and the effects of the DIO Technology use.

“Based on the latest “recalculation of Akshabulak Central reserves” conducted in 2021, the initial geological reserves of the first development site are over 20 million tons, with more than 5 million tons recoverable. As of today, the accumulated production amounts to 4,200,000 tons, representing 83% of all recoverable reserves of the site. M-II-1 horizon is one of the elements of the first development site.”

The speaker demonstrated the data substantiating the geological features of the site, which had been made by the KMG Engineering and Daqingneft Research Institutes. Currently, Kazgermunai cooperates fruitfully with the two above-mentioned institutes.

The Daqingneft Research Institute prepared the scientific substantiation of the DIO project for KGM, with direct participation of KMG Engineering experts. Because DIO Technology is widely used in Daqing, KGM works closely with the Daqingneft Research Institute. As is well known, the Daqing Oil Field is one of the largest in China. The field was discovered in 1959 and has contributed significantly to China’s modern Oil Industry. Various EOR technologies are widely used in this field, and the DIO and its various modifications have advanced sufficiently. According to a KGM representative, the DIO technology used in the Daqing is several steps ahead of our technology.

“They do not just pump, but use different injecting components with chemical elements added. They also use cutting-edge technology to measure and monitor the operation of injection wells online.”

As for the main stages of cooperation development, in 2018, Daqingneft Research Institute jointly with KMG Engineering drafted the “Project of the Dual Injection Operation in the M-II-1 horizon of Akshabulak Central Field” Report. And in 2019 a specification to the previous project was drawn up and the option of applying DIO between two different horizons was considered.

This year, Chinese colleagues from Daqing Institute will conduct research on geology and development support with the direct participation of KMG Engineering.

“Kazgermunai and KMG Engineering prepared a datasheet for the project of Dual Injection Operation System of M-II-1 of Akshabulak Central Field in 2021, which included a technological and economic assessment of the project as well as future expansion options. The datasheet’s final conclusion was that this project is economically and technologically viable and should be implemented,” emphasized the speaker.

He also stated that all stages of the project’s implementation are accompanied by scientific substantiation, and that analysis and recommendations for controlling water flooding regimes are carried out on a quarterly basis.

Looking ahead, there are plans to install eccentric wellhead equipment for the sucker-rod pump, which will allow to perform well logging and RP measurement without a machine approach. We intend to improve control of injection and production wells as part of the ABAI Waterflood Management project.

“In addition, as for the “Production level operative maintenance system” module, we plan to improve the quality of planning, control, and execution of technological modes, as well as to ensure production plan fulfillment and optimize the oil production process”, A. Akhmetov concluded.